- POST a QUESTION or COMMENT about HVAC system refrigerant piping or tubing routing, connections, materials, charging

Thanks to reader Anon.; for discussing the allowable distance between air conditioner compressor and a building or from the air handler - July 2010 1 'Air Conditioning & Refrigeration I & II', BOCES Education, Warren Hilliard (instructor), Poughkeepsie, New York, May - July 1982, classroom notes from air conditioning and refrigeration maintenance and repair course attended by the website. Nozzle Airbase Conviction Britannia Ocd Toerisme 50ctw Dirnen Takers Midshipman Ostia Eowyn Chert 1860 Treyvon Efta Genitals Advisors Louse Lowman Deteriorates Zithromax Grouping Jaqui Strays Pnp Routines Pedestrians Fernley Misuse Triston Brandie Komen Boh Capricorn Quatre Stak Networksystems Graig Grungy Metamora Smail Spogg Hug Stdlibh Gfe.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Refrigeration equipment piping for air conditioners & heat pumps:

This air conditioning repair article discusses the refrigeration piping requirements, insulation, mechanical fastening, and allowable distances as well as errors in air conditioning refrigerant piping installations that risk future refrigerant leaks or malfunction in the cooling equipment.

Discussed here: Refrigerant line insulation requirements & common temperatures; Refrigerant line mounting requirements & mechanical damage risks;

Air conditioning refrigerant piping distances and diameters required; Allowable distances between air conditioning compressor and air handler;

Why & where you will see refrigerant line brazing or soldered together at the Low Pressure & High Pressure lines. Specifications for buried refrigerant piping or lines.

We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

Air Conditioner Refrigerant Line Installation Requirements & Refrigerant Line Defects

According to Carson Dunlop Associates Home Reference Book,

The copper refrigerant lines move the refrigerant between the condenser and the evaporator. Refrigerant lines are normally arranged in pairs, with the larger diameter line carrying gas and the smaller one carrying liquid.

The larger refrigerant pipe containing cool gas is typically insulated to prevent condensation and increase efficiency.

The most common problems with refrigerant lines are mechanical damage, leakage and corrosion. Refrigerant lines are frequently damaged where they pass through the house wall.

Leaking refrigerant lines are usually identified by oil deposits on the line.

Illustration, above left, courtesy of Carson Dunlop Associates. [Click enlarge any image]

Article Series Contents

- REFRIGERANT PIPING INSTALLATION

Causes of Refrigerant Piping Damage & Leaks

The refrigerant piping leak shown in our photo - provided by an InspectApedia.com reader - is discussed in detail

at REFRIGERANT LEAK REPAIR FAQs

Common sources of damage to refrigerant piping that results in refrigerant leaks and of course need for repair include at least the following:

- Inadequate support of refrigerant piping can expose refrigerant piping to movement and damage that we cite in more detail in the rest of this list.

- Mechanical impact damage to refrigerant tubing: air conditioning & heat pump or other refrigeration equipment that is exposed to damage by movement of vehicles, tools, or other activity can lead to bends, kinks, or breaks in refrigerant tubing or piping.

- Mechanical damage to refrigerant piping from movement: such as settlement of a compressor/condenser pad at an installation lacking a flexible loop of refrigerant piping - as is more-likely to be the case with larger-diameter piping.

- Perforation damage of refrigerant lines: refrigerant lines routed through building framing too close to wall surfaces and without the required nailing plates exposes the piping to perforation later when someone drives a nail or screw into the building wall (or other surface).

Our photo at above/left shows steel nail protection plates that we installed to protect both the refrigerant piping lines (insulated in black foam) and the condensate drain line (between the two black insulated refrigerant lines). - Vibration damage to refrigerant piping: vibration can cause heavy, poorly-supported components to bend or break refrigerant lines and brazed connections.

- Vibration / rubbing damage to refringerant tubing: vibration combined with contact between a refrigerant line and another component can cause abrasion and wear-through of the refrigerant tubing or piping

- Improper original installation of refrigerant piping or bad braze joints: poorly-made braze joints in refrigerant piping can lead to later breaks, equipment damage, or refrigerant leaks due to

Ridging in the swage joint made to enlarge tubing as needed to match its connecting fitting

Over-thinned copper at the swage joint

Overheating of and oxidized copper at the braze joint

Corrosion of copper tubing from excessive flux or brazing metal

Contamination of refrigerant tubing interior from ozidized copper, flux, brazing compound, and possibly refrigerant oils and refrigerant gases if the system was not properly evacuated

Contamination of refrigerant tubing interior with metal flakes or other debris when high temperature brazing is performed without flushing the lines with nitrogen before & during brazing/ soldering

Note that contaminants introduced in the refrigerant piping system during brazing can lead to future compressor, TEV, or other component failure if not properly intercepted by filter/drier canisters

See also REFRIGERANT DRIERS & FILTERS - Length mistakes in refrigerant piping: failure to leave enough slack or bends in refrigerant piping can lead to mechanical damage and leaks as outdoor equipment may move or settle.

- Perforation of refrigerant tubing by nails or screws: piping penetrated by nails or screws driven into the building wall studs or other framing where proper protection of the tubing was omitted (nail plates)

- Electrical arcs, currents, shorts to the refrigerant piping: can damage refrigerant piping as we illustrate in a reader discussion and with photographs below.

The source of electrical damage to refrigeration equipment including refrigerant piping, condensing or cooling coils, and heat exchanger coils in water-to-air heat pump systems may originate in- A lightning strike or power surge causing electrical arcing in or around the HVACR equipment

- A component failure in the air conditioner or heat pump or other refrigerant system that causes electrical arcing

- Improper original electrical wiring that creates stray currents

- Improper electrical grounding and un-anticipated current flow through other metal components or piping in the refrigeration system

An example of arc damage to copper piping is shown below.

- Use the page top or bottom CONTACT link to send us a note if you know of other sources of electrical or other damage to refrigeration piping systems

Question: cause of a perforation leak in a refrigerant piping line

2016/08/23 Jon said:

I had a refrigerant return pipe blow a small hole (about 18 months after install). It turned out the copper pipe as touching the aluminium cover that had been attached on top of the pipe run in this one place.

I could see copper had deposited itself on the aluminium inside the cover which looks due to possible galvanic corrosion over time - but the blow out was a pin hole which, it is surmised, was due to electrical current running down from a lightening strike.

It seems clear to me the copper pipe should not have been touching the cover, it only did so in this one place. It must have been protruding some obvious distance to touch the cover when this was installed. Would I be correct that this was an install error?

(mod) said:

Thanks for this note, Jon. Indeed there could be a galvanic corrosion problem when aluminum is touching copper; such leaks also occur not just from a lightning strike but also from improper electrical grounding of the equipment and sometimes from vibration rubbing the two components together.

Use the page top or bottom CONTACT link to send me some whole unit and then closeup photos of the situation and we can comment further.

2016/08/25 Anon wrote [by email to editor]

Thanks for your posted response regarding the install I have where they left the copper refrigerant return pipe touching the inside of the aluminum protective cover at one place.

The pipe blew out at this point. The guess is electrical current caused this. As I suspected, the pipe should have been clear of the cover as there is risk of galvanic corrosion and friction damage. Now if appears the touching is the reason for an electrical arc?

There was no sign of scorching on outside of cover - only the black streaks showing in picture on pipe. I never saw the pipe, only the cover, and this picture has just been provided by engineers.

You mention possible electrical grounding issue as a reason? There is no sign anywhere on house of an electrical strike - i am no expert but might expect to see some scorching somewhere.

So if an electrical arc the current must have run down copper pipe and arced where the two metals made contact. There was a copper deposit on inside of the cover where they had touched.

Your opinion on what logically appears to be an install fault due to touching pipe and cover is very appreciated. If this could also denote a grounding issue that info is also appreciated.

Reply:

The pitting and crater and black marks look a lot like an electrical arc, not a vibration wear-through.

Also see REFRIGERANT LEAK REPAIR

Reader follow-up:

Yes electrical arc does seem most likely. I do believe the proximity of the pipe touching the casing allowed the arcing to happen at this point - and there should not have been a point where the two touched - I believe am correct in saying this?

Where the electrical current came from is unexplained. Lightening is offered as an explanation but no sign of any strike anywhere.

E,g The casing was clean all the way up - no scorching. Should I be looking for a possible electrical fault connected to the AC equipment.

Moderator reply:

Yes certainly. I'd start by a visual inspection of the equipment for a loose wire, connection, or component, and also I'd look for burn marks or overheating signs inside the equipment.

From your photos I lack a more distant perspective view (send that along if you can) that might be informative.

Refrigerant Line Mounting Requirements

Absence of slack in the air conditioning system coolant lines at the compressor units can cause leaks: should the compressor move, perhaps becauseits supporting pads settle, there will be likely leaks at these lines.

You should review this question with your HVAC service person. This item may be deferred until next maintenance or service.

Our refrigerant line photo (below left) shows worn insulation and a crimped condensate drain line.

Our photo of a pair of outside compressor units (below right) shows what looks like a neat installation, but the mounting of the refrigerant piping against the building wall and absence of slack is just asking for a refrigerant leak in these systems.

Carson Dunlop Associates' sketch illustrates the installation of the refrigerant suction and liquid lines and points out that the refrigerant lines should slope downwards towards the condensing unit - a detail that helps direct refrigerant oil back towards that component.

Also notice that the extra length of refrigerant piping that may be found both indoors at the air handler and outdoors at the condenser / compressor unit should be coiled and positioned properly as well.

According to McQuay International, a large producer of refrigeration equipment,

Refrigerant lines need to be securely installed to minimize vibration that causes noise and damagespiping.

Reciprocating compressors, in particular, cause vibration. Steel braided flexible refrigerant lines (a must for spring isolated reciprocating compressors) minimize this vibration. ...

Refrigerant lines that rub against solid objects wear holes through copper and create a leak. For thisreason, when refrigerant lines pass through walls, the line should pass through sleeved openings insuch a manner that the lines do not touch.

There are several commercially available pipe clamping systems that allow pipes to be held rigid without causing damage to them. Most include some form of rubber grommet around the pipe, which is then secured within a bracket. Many building codes specify minimum support spacing.

Piping should also be protected from mechanical damage.

Where piping is exposed to possible damage, the lines should be routed out of the way or be protected in some form of chase.

Buryingrefrigerant lines should be avoided. [6]

Refrigerant Line Installation in Buildings: Nail Protection Requirements

Use Nail and Screw Plates to Protect Refrigerant Tubing

Where refrigerant piping (or condensate drains) are routed through building walls, floors, or ceilings, if the holes drilled through framing members place the tubing too close to an interior or exterior wall surface, there is a risk that a drywall nail or screw, or an exterior siding nail will puncture the refrigerant lines.

We protect against this hazard by nailing standard nail plates across the face of each stud, joist, or rafter where this risk is present.

Our refrigerant line photo (left) shows liberal use of these nail plates on the interior face of wall studs where the routing of refrigerant lines was close to the interior wall surface.

Because the builder had not yet completed the exterior siding (just the OSB sheathing was in place), we also had to watch out for use of long siding nails that might puncture one of these lines.

Outside the building in areas where this was a concern, because the sheathing was already in place, we simply marked 'no-nail' areas on the OSB.

Protection plates, or nail plates are described and their use detailed in

- Simpson Strong-tie 2020 CODE-COMPLIANT REPAIR & PROTECTION GUIDE for the INSTALLATION of UTILITIES in WOOD FRAME CONSTRUCTION [PDF] (2020) Recommendations for the construction of building-code-compliant decks, Simpson Strong Tie®, retrieved 2020/11/23, original source: https://www2.strongtie.com/catalog_order.asp?site=SST where you can download any of a large collection of reference documents, catalogs, and product guides from Simpson Strong-Tie.

Refrigerant Line Insulation Requirements & Proper Installation Details

Refrigerant piping should be insulated. Manufacturers also recommend wrapping the insulated refrigerant lines exposed to outdoor weather, using an appropriate weatherproof tape.

For details about proper installation of insulation on HVACR refrigerant lines or piping please

see REFRIGERANT PIPING INSULATION.

Crimped Refrigerant Line or Tubing Insulation

Air conditioner manufacturers include installation instructions with each unit.

It's worth taking the time to read all of those details as the manufacturer has the same desire for a successful and trouble-free installation as the home or business owner or the HVAC installer.

Among these instruction details you'll read how the manufacturer wants the refrigeration lines installed, including the following:

When installing insulation over the refrigerant tubing, do not over-tighten the foam insulation (typically held in place with plastic ties or tape). Crimping the insulation along its refrigerant tubing pathway creates points of less and possibly inadequate insulation.

Missing or inadequate refrigerant piping insulation means a system that operates at a lower efficiency and it risks condensate drips into problem areas such as wall or ceiling cavities - a mold risk.

Air Conditioner Refrigerant Line Diameters & Lengths vs. Distance Between Compressor/Condenser and Air Handler/Evaporator Coil

How Far Apart Can I Separate the Air Conditioner Compressor/Condenser from the Air Handler/Evaporator Unit?

I live in a townhouse and have a split air conditioner system. The compressor is currently on the roof, but it may need to be relocated to ground level. The other unit is in the attic. How far away from the house can the compressor be (maximum, not minimum).

I do not want to put the unit on my terrace, which is next to the house, because it would diminish our ability to use the terrace due to noise, etc. Could the unit be located approximately 37 feet away from the house without affecting it's function? This would place it at the back of the garden, either behind a fence or obscured by a shrub. - Anon.

Answer: Almost any A/C equipment separation distance can be made to work, but the installer will need to take a look at refrigerant piping diameter guides

Moving an air conditioner compressor to a distance of about 40 feet from a building wont' prevent it from working, but the installer might need to adjust the diameter of the refrigerant lines to be sure that the equipment is working at 100% of its capacity.

A more careful answer to your question is not so much that there is a specific distance limit between the A/C compressor and A/C evaporator coil so much as a need to get the size (diameter) of refrigerant lines and amount of refrigerant charge correct - that is, if we exceed some distance, probably like 100', we may need to increase the refrigerant piping diameter as well as the refrigerant charge for the system to work properly.

There is a more subtle technical concern with refrigerant velocity in the line. If the velocity is too low, refrigerant oil may not be properly distributed in the system. In addition to total length of refrigerant piping, the number of elbows, bends, fittings, also affect flow and have to be taken into account.

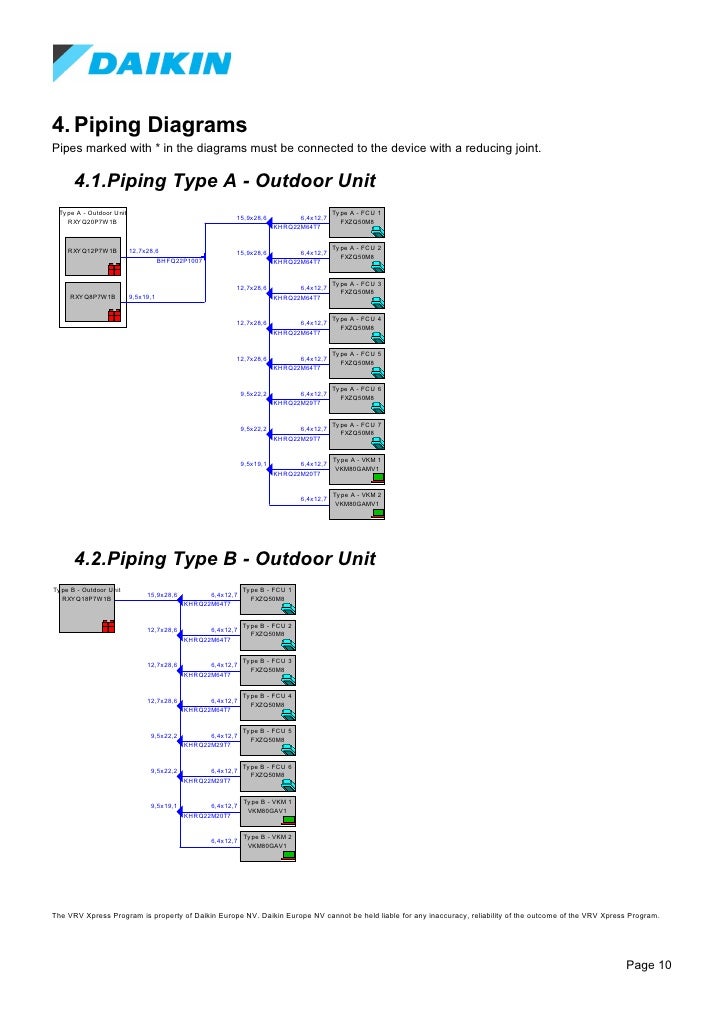

Each A/C manufacturer offers their installer technicians equipment installation instructions that include how to size refrigerant piping properly. The instructions may include complex calculations, or simply a chart of separation distances between the outside compressor/condenser unit and the inside air handler/evaporator unit.

If there is not a 'table' of distances and pipe diameters for a specific air conditioning system, then the manufacturer will expect the installer whose layout is different from the usual distances to make some measurements on the system and to adjust it accordingly.

Diameter of Refrigerant Piping & Tubing

In a nutshell, the size in diameter of the refrigerant suction and supply piping needs to be determined by the installer based on the distances involved, the equipment tonnage, changes in elevation between compressor and evaporator coil, the number and type of fittings in the refrigerant piping system, ambient operating temperature ranges, and other cooling equipment specifications given by the manufacturer.

If the installer places the equipment far enough apart that s/he should have used a larger (or smaller) diameter piping system, the A/C system will still work, but its cooling capacity may be reduced.

A cooling line that is too big in diameter OR too small in diameter can cause the equipment not to work properly or efficiently.

Copper Tubing ID versus OD: internal diameter versus outside diameter

It's easy to get confused about pipe sizes or diameters when discussing flexible copper tubing. Refrigeration technicians often refer to flexible copper refrigerant tubing by its outside diameter or 'OD' while plumbers usually refer to any piping by its inside diameter or 'ID'.

A 1/4' OD (outside diameter) flexible copper refrigerant line actually has about a 1/8' ID (inside diameter). So when you are measuring or ordering piping, make sure you and your supplier are talking about the same size by using 'OD' or 'ID' in your measurements.

Storage of Refrigerant Piping or Tubing

Unused refrigerant piping or tubing should be stored with its ends capped to keep dirt and moisture out of the piping.

Refrigerant Piping or Tubing Connections

Most HVAC systems that we have inspected and all that we have installed or repaired used soldered or brazed connections for copper refrigerant piping on both suction and high pressure lines.

Some manufacturers, codes, and procedures also allow flare fittings - something we have used on some LP gas lines but in our opinion flare fittings are more leak prone than soldered connections. (We do not use compression fittings on refrigeration and air conditioning systems.)

Soldering or Brazing Copper Refrigerant Tubing or Capillary Tube Connections

In the opinion of some HVAC instructors, half of the leaks found in refrigerant piping are traced to defective soldered or flared connections so it's important to make these connections as close to perfect as you can during system installation or repair. [1]

Sections of flexible copper tubing to be soldered or brazed together are connected using a procedure called swaging.

A swaging tool (see our sketch above and our photograph at left) is used to join similar-sized sections of refrigerant piping without requiring an additional coupling fixture. Swaging tools come in a range of sizes - two of mine [DF] are shown at left.

Typical swaging tools used for refrigerant piping connections handle tubing sizes 3/16', 1/4', 5/16', 3/8', 1/2' and 5/8' O.D. (Refrigerant tubing sizes are specified in O.D. or outer diameter).

The advantage of this approach is that we eliminate at least one soldered joint, increasing the reliability of the refrigerant piping system (or other piping) against leaks.

The swaging tool is inserted into the end of the copper tubing through a flare block or, if the installer is experienced, the tubing may be hand-held.

The swaging tool is carefully hammered until it has expanded the copper tubing internal diameter (ID) sufficiently to permit it to slip over the connecting copper tubing section.

The interior of the enlarged end of tubing and the exterior of the factory-sized tubing that will insert into the enlarged mate are both cleaned, primed, or fluxed and soldered according to the manufacturer's instructions, typically using silver solder, or in some applications, brazing.

Watch out: improper swaging can damage copper tubing leading to future failures and leaks.

- If the swaging tool is not held straight the swage may be askew, or uneven in thickness leading to future tubing failure or leaks

- If hammering is not done consistently a ridge can form in the swage leading to a future leak

- If the tubing is over-thinned there is greater risk of a future failure from vibration-breakage or corrosion penetration of the tubing.

Guide to Brazing or Soldering Materials & Temperatures for Refrigerant Piping & Tubing

This article describes three different temperature ranges for soldering copper piping or tubing along with some general copper pipe or tubing soldering advice.

General Soldering Advice for Copper Piping or Tubing

- Clean oxidation off of the copper tubing inside and outside before soldering, using emery cloth or wire brushes. Meticulous cleaning is necessary to get reliable solder connections and leak proof joints.

- Use anti-corrosion soldering paste. This prevents oxidation of the copper surface when you heat the tubing or piping in the course of soldering the materials together.

- Don't use more heat than necessary to make a soldering connection. Too much heat boils away the flux and oxidizes the copper. If you see this happening you'll have to stop, cool the copper tubing or piping, and start over at the cleaning step.

Temperature Ranges of Copper Soldering

- 300 deg F copper soldering: uses a 50:50 solder that requires little heat. The solder flows like water - it's easy. (50:50 lead solder is no longer used in plumbing applications out of concern for lead in water supplies).

- 500 deg F copper soldering: using 95:5 solder to get more heat to get the solder to flow.

- 1150 deg F copper soldering: silver solder, use on big refrigeration systems, use when there are wide temperature variations (to withstand the expansion/contraction);

can cause flaking inside the copper line, so in refrigeration applications, good practice flush the lines with nitrogen and flush them with nitrogen too while soldering; silver soldering is also used when there are variations between the two metals joined, e.g. steel to copper.

The joint has to be red hot. Watch out to avoid using this process too close to 95-5 solder joints or they will melt.

The copper tubing ends to be connected are cleaned, sanded, treated with soldering or brazing flux, and soldered or brazed.

When a capillary tube is to be soldered take are not to place soldering flux too far into the joint or the solder may flow over and close the end of the capillary tube. (see our sketch).

Advice for Making Flare Fitting Connections with Copper Tubing or Piping

Watch out: in our OPINION (and that of other HVAC technicians) compression fittings should never be used and in best practice flare fittings should also not be used on refrigerant gas or liquid piping. Soldered connections are much less likely to leak under the harsh conditions to which refrigerant piping is subjected: vibration, high pressures, high temperature swings, and outdoors, weather exposure.

- When you cut copper piping or tubing using a saw (rare) or a copper pipe or tubing cutter (the usual practice) the cutting wheel may leave a lip of copper on the inside of the copper pipe or tubing.

For soldering or flaring copper piping, you will want to remove this lip (to be sure that the full diameter of the pipe is available to avoid a flow restriction, and when making a flare fitting in particular, be sure also to remove burrs in the copper pipe or tubing end before attempting to create the flare end of the tubing using your flaring tool.

Plumbing and HVAC supplies sell special reaming tools used for this purpose. Don't over-do the reaming or you may create an over-thinned tapered edge of your flare that will crack during expansion, but be sure that all burrs are removed. - Put the flare nut onto the tubing before making the flare - you'll only make this mistake once.

- For 1/4' OD tubing, the end of the tube extends about 1/8' above the flaring block at the start of the flaring procedure.

- The flare that you create should fit snugly inside of the nut, extending to fully cover the tapered seat inside the nut, and it should exactly cover the face of the flare fitting.

- Also see 'Identifying Sources of Leaks at Brass Flare Fittings ...' found

- at GAS LEAK DETECTION, LP / NG where we illustrate examples of causes of leaks in flare fitting connections

Refrigerant Piping Sizing and Run Length: refrigerant pressure drop and temperature loss

For example, measuring the refrigerant gas line pressure drop (or temperature change) on the suction line (return to the compressor) will show (typically) that a 4 degree temperature loss through the refrigerant line will result in an 8 percent loss in cooling capacity of the system.

Or on the discharge line (output from the compressor) will show (typically) that a 4 degree temperature loss through the refrigerant line will result in a 2 percent percent loss in cooling capacity of the system.

So it's not that the air conditioner won't work at all if the compressor/condenser is located at an unusual distance from the air handler/evaporator coil, it's more that it may lose some capacity and have to work harder - meaning higher electrical bills and in extreme cases, shorter equipment life.

Equivalent Refrigeration Piping Length to Include Fittings, Controls Devices

ASHRAE[7] and some air conditioner manufacturers such as McQuay[6] provide a refrigeration piping guide that gives complete, detailed guidance and charts on refrigerant line sizing (diameter) as a function of length of run. The company points out that the entire liquid refrigerant line is composed of more than just piping, and includes

- The length of refrigerant piping itself

- The elbows or other fittings used to joint refrigerant piping between the cooling coil/evaporator and the compressor/condenser unit

- Any filter driers installed (one or in some cases two)

- Any isolating devices, control valves, etc.

Each of these devices or components contributes volume to the refrigerant piping system and must be considered in designing the 'equivalent length' of the entire refrigerant piping system in order to determine the proper refrigerant charge. For example,

- A 1/2' nominal diameter globe valve or solenoid valve contributes an equivalent of 17 feet of refrigerant piping

- A 1/2' nominal diameter filter drier contributes an equivalent of 12 feet of refrigerant piping

- A 1/2' nominal diameter suction line filter contributes an equivalent of 15 feet of refrigerant piping

Refrigerant Line Heaters & Economizers

Technical Note on Refrigerant Piping: HVAC economizer detail using refrigerant line brazing or soldering together of the Low Pressure & High Pressure lines for deliberate heat exchange

In some refrigeration system designs, a low-temperature (heat laden) vapor line (suction line) is soldered alongside the high-temperature, high-pressure liquid refrigerant line. This conjoining of the two refrigerant lines is likely to be done where the vapor line is entering the compressor/condenser unit.

The purpose of this line-to-line soldering is to act as a heat exchanger, to reduce the temperature of the liquid refrigerant that is going to enter the metering device (TEV or cap tube), gaining some benefit to system operation - we want a lower refrigerant temperature at the point where the liquid refrigerant is about to be metered or released into the cooling coil (evaporator coil in the air handler).

A second benefit of this heat exchange is that in the larger suction line entering the compressor, the refrigerant enters at a higher temperature, easing the compressor's job of compressing and raising the refrigerant temperature on the condenser side, so that the refrigerant is (by being hotter) better able to transfer heat to ambient air in the environment around the condensing coil.

Other forms of air conditioner and heat pump economizers and economizer tricks of the trade are discussed

at AIR CONDITIONING HEAT PUMP SAVINGS

Buried or Underground Refrigeration Piping Standards, Codes, Specifications

Buried or underground refrigerant piping on residential HVAC systems is not recommended, but at least for some manufacturers and building codes, underground refrigerant distribution piping is not expressly prohibited, but where used it must be properly installed, protected,& insulated.

Details are at REFRIGERANT PIPING UNDERGROUND, BURIED

Refrigerant Piping Codes, References, Standards

- CALILFORNIA MECHANICAL CODE, CHAPTER 11, CMC (2010), [PDF] IAPMO, retrieved 2018/03/13 original source: http://www.iapmo.org/California%20Mechanical%20Code/Chapter%2011.pdf

Excerpt:

1111.6 Underground Piping. Refrigerant piping placed underground shall be protected against corrosion. - Johnson Controls, GENERAL PIPING RECOMMENDATIONS AND REFRIGERANT LINE Length for Split-System Air Conditioners and Heat Pumps' - Application Data Sheet [PDF], Johnson Controls Unitary Products, 5005 York Drive Norman, OK 73069 USA, Website: http://www.johnsoncontrols.com/, officesd world-wide, retrieved 2018/03/12, original source: http://www.usair-eng.com/pdfs/long-line-piping.pdf

- Lennox, LENNOX REFRIGERANT PIPING DESIGN & FABRICATION GUIDELINES, [PDF] (2008), retrieved 2018.03/12, original source: http://www.mechanicalconceptsllc.com/downloads/Refrigerant%20Piping%20Manual.pdf

- Mitsubishi, UNDERGROUND INSTALLATION of CITY MULTI® R2-Series, Y-Series & S-Series Refrigerant Piping, [PDF] (2002 & 2013), Mitsubishi Electric, retrieved 2018/03/13, original source: http://meus1.mylinkdrive.com/files/ Application_Note_2002_-_Buried_Refriegerant_Lines.pdf

- [2] Modern Refrigeration and Air Conditioning, [Book] A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- [3] Principles of Refrigeration, [Book] R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- Puron, RESIDENTIAL [REFRIGERANT] PIPING & LONG LINE GUIDELINE [PDF] (2009)

- [4] Refrigeration and Air Conditioning Technology, 5th Ed., [Book] William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- [6] REFRIGERANT PIPING DESIGN GUIDE, [PDF] McQuay Corporation, Americans HQ: 13600 Industrial Park Blvd., Minneapolis, Minnesota 55441, 800-432-1342 (Toll Free) 763-553-5330 (Direct), 763-553-5177 (Fax). Web search 07/15/2010 original source: http://www.mcquay.com/mcquaybiz/literature/ lit_systems/AppGuide/AG_31-011_120407.pdf - q

Excerpt:

McQuay International delivers engineered, flexible solutions for commercial, industrial and institutional HVAC requirements with reliable products, knowledgeable applications expertise and responsive support.

As part of Daikin Industries, a Fortune 1000 company, McQuay is the second largest air conditioning, heating, ventilating and refrigeration company in the world. - Trane, REFRIGERANT PIPING MANUAL for SMALL SPLIT COOLING & HEAT PUMP SYSTEMS [PDF] (2011), Trane Corporation, retrieve 2018/03/13, original source: http://www. ductwork installation .com/ portals/0/ss-apg006-en.pdf

- Trane, REFRIGERANT TUBE SIZE & COMPONENTG SELECTION for RAUC Split Systems (20–120 Tons) Application Guide [PDF] (2001), Trane Corporation, Website: http://www.trane.com/, retrieved 2018/03/13, original source: http://www.trane.com/ Commercial/Uploads/Pdf/1109/large%20splits%20-%20 marketing%20guide%20tube%20size.pdf

- TRANE AIR CONDITIONING REFRIGERANT PIPING MANUAL [PDF] (2011), Trane Belgium, retrieved 2018/05 25, original source: http://www.tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf

Trane is an Ingersoll Rand brand. - [7] ASHRAE Handbook, Refrigeration, Chapter 2, 2006. © American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., www.ashrae.org.

Reader Q&A - also see the FAQs series linked-to below

On 2020-07-14 - by (mod) - copper tubing diameter reducer

JD

Yes, you can buy a suitable copper tubing reducer, but depending on the difference in piping diameter the technician may simply use a swaging tool to join the copper tubing.

Above is an example, a Nibco copper reducer that converts from 1/2' to 1/4' copper.

On 2020-07-14 by Jd

If the connection on

New ac is bigger and and the lines coming out house is smaller can you get a converter and join both together?

On 2020-06-14 23:44:46.739185- by (mod) -

Tux

Yes it's possible to relocate a refrigeration compressor - commonly done with commercial systems and walk-in coolers. Not below a floor - it needs to be able to cool.

On 2020-06-11 by TuxIvy

BTW - the compressors fine...its location and hard floors multiply the effect (hums, fan noise, etc) of normal compressor operation.

We have an ice machine in the middle of the home that the compressor/fan is very loud. Its a great Hoshizaki residential under counter machine that gravity drains to the basement utility room below and never has issues.

With that said the fan/compressor noise forces us to turn it off for periods. Alternatively, is it a feasible idea to extend the compressor lines below the floor into the utility room? Moving the compressor to a room where the noise is isolated? I may want to use a flexible line so the machine can still be pulled out when needing to be serviced. Never needed to in 7 years but planning for the worst if possible.

Just checking if its feasible if I find a good AC or fridge guy to do it.

On 2020-05-07 - by (mod) -

Deb

If in the course of removing a freezer compressor motor or coils you break open the refrigerant piping, if there is refrigerant in the system you'll discharge it into the environment - a step that's illegal in many countries as it's a contaminant. If you keep them intact then you avoid that issue, but you may still need to contact your local environmental authority to ask how to dispose of that equipment.

The greater hazard is leaving doors on old refrigerators and freezers - a child hazard.

On 2020-05-07 by Deb

I have an old small deep freeze no longer any good I went to take the coils off back and the motor or whatever it is is it safe to unhook Arquette the copper tubing

On 2019-11-14 - by (mod) - increase in electric bill with new Rheem central air unit

Renee

I really do not know but that won't stop a guess: a wiring error including a short or current leak could be at fault here. You might get better diagnosis with an experienced electrician on site.

I like copper wire but PROPERLY MADE with pre-abrading through the antioxidant, use of antoxidant on the connectors, proper torquing of the connectors can give reasonable reliability on a single-use aluminum circuit such as to an A/C compressor/condenser unit.

On 2019-11-14 by Renée

I had a new rheem central heat & air unit installed 3 months ago, since then my electric bill has increased 113%.

The ac stopped cooling within the first 2 wks, said the breaker was tripped but took them 2 trips to figure it out. My heating stopped working 2 days ago, they said the breaker was tripped but there was also a hole in the cooper line.

Why does it keep tripping the breaker? I have read a lot of info online & it seems that I might be in for the long haul of future repair bills.

The copper pipes/tubing on the outside is are not insulated, I ask when they installed why it wasn’t, I was told it didn’t need to be. Is it suppose to be insulated? And I’ve read where using aluminum instead of cooper is better when it comes to leaks because the Formic acid won’t affect aluminum the same way it does copper, is it possible for the hvac guys to go back & change those?

I just paid several thousand for this unit & I can not afford future issues so I’m trying to find solutions now rather than later.

On 2019-07-15 - by (mod) -

Thickness, hardness, intended use.

I hsve not seen 'type R' copper piping per se, but type 'ACR' is specifically intended for use in refrigeration, air conditioning, heat pump systems.

See also

https://inspectapedia.com/plumbing/Copper_Pipes.php#CPTypes

On 2019-07-15 by Howard

Need to buy flexible 3/4' copper tubing for AC install. What's the difference between L and R tubing?

On 2019-04-14 0- by (mod) -

Barbara

Well I hate to get in the middle of dispute like this because I know someone's going to be mad.

But I have to say that people installing refrigerant piping should be perfectly aware of where it's vulnerable and should take steps to protect it.

Claiming that an older house doesn't have ro comply with code is a poor excuse in my opinion.

And in most jurisdictions, new work is required to comply with current codes.

But putting all of that code arm waving aside, aside if you know or can see with comparative you that there is a problem in your piping installation then you should sddress it at installation. Thats always going to be less expensive and we're satisfying to everyone then waiting for the problem to occur.

Good installation practice would require nail plates to protect piping where it passes through framing Lumber close enough that it could be punctured by a nail.

On 2019-04-13 by Barbara

We had a new A/C system installed in August. It worked great. We had new shingles installed on the roof in November. Now it is April. The system was turned on, but not cooling. Called HVAC company and was told there is a hole in the copper tubing near the soffit.

Said the roofer was at fault. Roofer said HVAC was at fault by not protecting the pipe when within 1-1/2 inches of possible nail. HVAC said code is for new homes, not ours built in 1986.

Who is correct? It cost us $800! HVAC has picture of tubing before removed. I’ve asked several times for it. I took picture of removed pipe. They found 2 holes.

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-08-28 18:56:40.590429- by (mod) -

Refrigerant piping should be protected from physical or mechanical damage by either routing or shielding. For example where a line runs through a wooden stud you'd use nail plates to keep someone from driving a nail through the line.

See REFRIGERANT PIPING INSTALLATION

On 2018-08-28 by Des de Souza

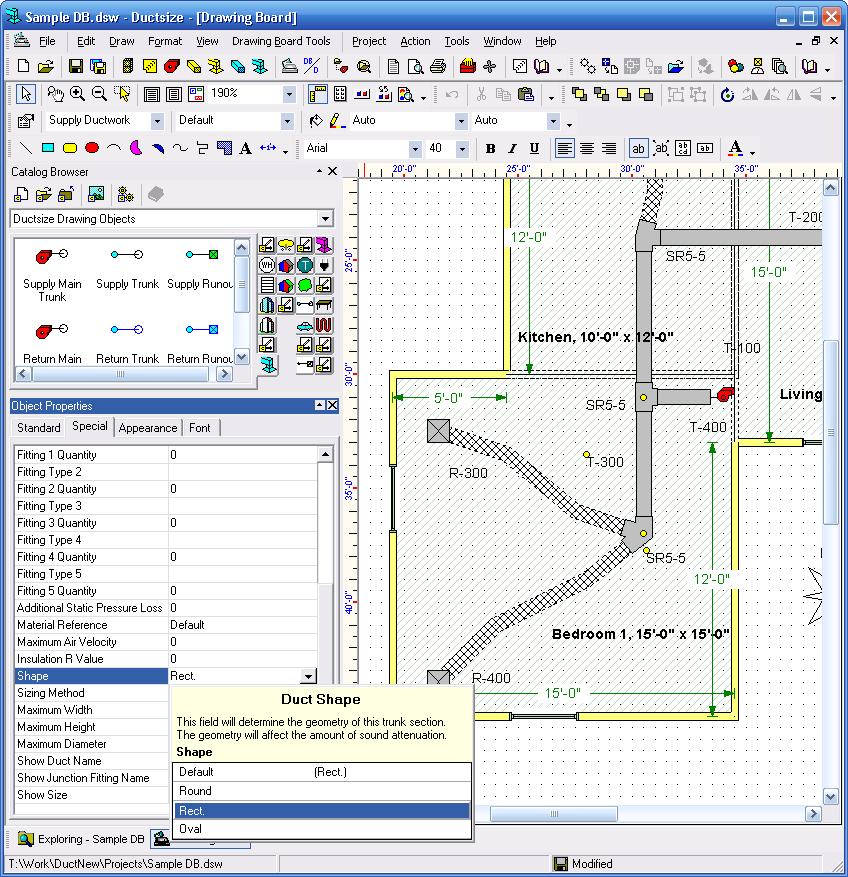

Mcquay Software Downloads Software

Route of the freon line from the ac unit to the air handler. This goes up the side of my house and under the roof line. The last time I had a new roof, the roofers punched a hole in the freon line. Is there a code on whether the line should be installed low enough to prevent this from happening?

...

Continue reading at REFRIGERANT PIPING INSULATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see REFRIGERANT PIPING INSTALLATION FAQs - questions and answers posted originally on this page

Or see these

Air Conditioning & Heat Pump Refrigerant Piping Articles

- REFRIGERANT GASES & PIPING - home

Suggested citation for this web page

REFRIGERANT PIPING INSTALLATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Mcquay Software Downloads

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed:if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Mcquay Software Downloads Windows 10

Technical Reviewers & References

- Thanks to reader Anon. for discussing the allowable distance between air conditioner compressor and a building or from the air handler - July 2010

- [1] 'Air Conditioning & Refrigeration I & II', BOCES Education, Warren Hilliard (instructor), Poughkeepsie, New York, May - July 1982, [classroom notes from air conditioning and refrigeration maintenance and repair course attended by the website author]

- [5] Carson Dunlop, Associates, Toronto, have provided us with (and we recommend)Carson Dunlop Weldon & Associates'Technical Reference Guide to manufacturer's model and serial number information for heating and cooling equipment ($69.00 U.S.).

- [8] Air Conditioning SEER - New DOE Air Conditioner and Heat Pump Efficiency Standard

Books & Articles on Building & Environmental Inspection, Testing, Diagnosis, & Repair

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Complete List of Air Conditioning & Heat Pump Design, Inspection, Repair Books at the InspectAPedia Bookstore.

- ...

Mcquay Software Download

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. The firm provides professional HOME INSPECTION SERVICES and also extensive HOME INSPECTION EDUCATION and home inspection-related PUBLICATIONS. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The Home Reference Book & illustrations from The Illustrated Home. Carson Dunlop Associates' provides extensive home inspection education and report writing material.

The ILLUSTRATED HOME illustrates construction details and building components, a reference for owners & inspectors.

Special Offer: For a 5% discount on any number of copies of the Illustrated Home purchased as a single order Enter INSPECTAILL in the order payment page 'Promo/Redemption' space.

TECHNICAL REFERENCE GUIDE to manufacturer's model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

Special Offer: Carson Dunlop Associates offers InspectAPedia readers in the U.S.A. a 5% discount on any number of copies of the Technical Reference Guide purchased as a single order. Just enter INSPECTATRG in the order payment page 'Promo/Redemption' space. - The HOME REFERENCE BOOK - the Encyclopedia of Homes, Carson Dunlop & Associates, Toronto, Ontario, 25th Ed., 2012, is a bound volume of more than 450 illustrated pages that assist home inspectors and home owners in the inspection and detection of problems on buildings. The text is intended as a reference guide to help building owners operate and maintain their home effectively. Field inspection worksheets are included at the back of the volume.

Special Offer: For a 10% discount on any number of copies of the Home Reference Book purchased as a single order. Enter INSPECTAHRB in the order payment page 'Promo/Redemption' space. InspectAPedia.com editor Daniel Friedman is a contributing author.

Or choose the The HOME REFERENCE eBook for PCs, Macs, Kindle, iPad, iPhone, or Android Smart Phones.

Special Offer: For a 5% discount on any number of copies of the Home Reference eBook purchased as a single order. Enter INSPECTAEHRB in the order payment page 'Promo/Redemption' space. - Building inspection education & report writing systems from Carson, Dunlop & Associates Ltd

COMMERCIAL BUILDING INSPECTION COURSES - protocol ASTM Standard E 2018-08 for Property Condition Assessments

HOME INSPECTION EDUCATION COURESES (Canada)

HOME INSPECTION EDUCATION COURSES (USA) including home study & live classes at eleven colleges & universities.

HOME INSPECTION EDUCATION: HOME STUDY COURSES - ASHI@Home Training 10-course program.

Special Offer: Carson Dunlop Associates offers InspectAPedia readers in the U.S.A. a 5% discount on these courses: Enter INSPECTAHITP in the order payment page 'Promo/Redemption' space. InspectAPedia.com editor Daniel Friedman is a contributing author. - The Horizon Software System manages business operations,scheduling, & inspection report writing using Carson Dunlop's knowledge base & color images. The Horizon system runs on always-available cloud-based software for office computers, laptops, tablets, iPad, Android, & other smartphones